Modern aquaculture is an industry transformed. The push for higher yields and greater sustainability has led to the widespread adoption of intensive farming methods like Recirculating Aquaculture Systems and biofloc technology. At the heart of these systems is the need for powerful, reliable aeration, a task for which the roots blower for fish farming has become the undisputed workhorse. By delivering a constant, high volume of air, these blowers are the engines driving productivity, ensuring high dissolved oxygen levels, and maintaining optimal water quality.

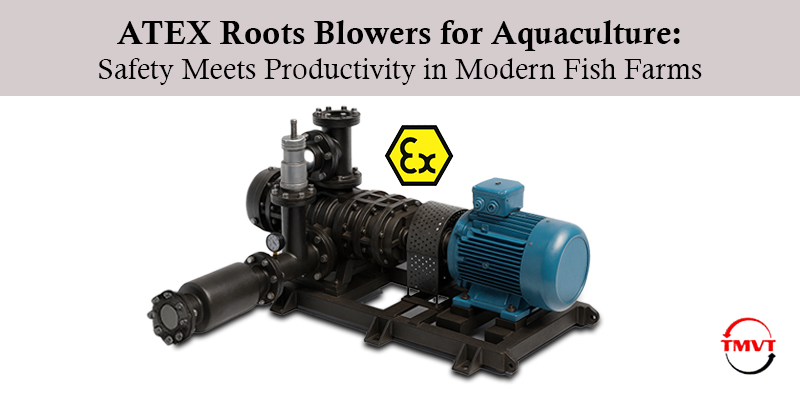

However, as aquaculture operations become more technologically advanced and enclosed, they begin to mirror industrial processes, introducing new and often overlooked safety challenges. The very biological processes that these systems foster can generate hazardous, flammable gases. This intersection of biological productivity and industrial risk is where ATEX certification becomes not just relevant, but essential. An ATEX roots blower in aquaculture is more than just an aeration device; it is a critical piece of safety infrastructure that protects the facility, its personnel, and its valuable stock.

Why Roots Blowers are Essential for Modern Fish Farming

The primary function of an aeration blower in aquaculture is to sustain life and optimize growth. Roots blowers, as positive displacement machines, are uniquely suited for this role, providing a constant and steady volume of air regardless of back-pressure. This consistent performance directly translates to several key productivity advantages.

- Consistent Dissolved Oxygen Supply: High stocking densities in modern fish farms place an enormous demand on the dissolved oxygen in the water. Roots blowers, connected to diffusers at the bottom of tanks or ponds, ensure a continuous and uniform supply of oxygen throughout the entire water column. This prevents stratification, eliminates low-oxygen dead zones, and reduces stress on the fish, leading to better health, improved growth rates, and higher survival rates.

- Superior Water Quality: Effective aeration is fundamental to water quality management. The circulation created by a roots blower helps suspend solids for removal and, more importantly, supports the aerobic bacteria that break down harmful waste products like ammonia. This process prevents the buildup of toxic gases and helps maintain a stable, healthy aquatic environment.

- Energy Efficiency and Reliability: Modern tri-lobe roots blowers are engineered for high efficiency, delivering large air volumes with lower power consumption compared to other aeration methods. Built with robust materials and simple mechanical principles, they are designed for 24/7 operation with minimal maintenance, offering the reliability that is critical for any aquaculture operation.

Flammable Gas Generation in Intensive Aquaculture

While the benefits of intensive aquaculture are clear, the concentration of biological activity in enclosed systems like RAS and biofloc tanks can create potentially hazardous environments. The same microbial processes that treat waste can, under certain conditions, produce flammable biogases.

The primary concern is hydrogen sulphide (H2S), a toxic and flammable gas produced by anaerobic bacteria. These bacteria thrive in oxygen-depleted zones that can form in:

- Settled Sludge: Pockets of accumulated fish waste and uneaten feed at the bottom of tanks or in sumps can quickly become anaerobic, creating ideal conditions for H2S production.

- Biofilter Dead Zones: While biofilters are designed to be aerobic, areas with poor mixing or insufficient flow can become anoxic, turning a water treatment component into a potential gas generator.

- Stagnant Piping: Sections of pipe with low flow can also accumulate organic matter and foster anaerobic conditions.

In these intensive systems, microorganisms can also produce methane (CH4). While typically in smaller quantities, both H2S and CH4 can accumulate in enclosed spaces such as pump rooms, filter buildings, or the headspace above tanks, creating a potentially explosive atmosphere. An ignition source in such an environment could lead to a catastrophic event.

The ATEX Solution: Engineering Safety into Aeration

This is precisely the scenario that ATEX certification is designed to prevent. An ATEX-certified, explosion proof blower for aquaculture farms is engineered to eliminate all potential ignition sources, ensuring it can operate safely even if flammable gases are present.

Key safety features of an ATEX-certified roots blower include:

- Spark-Free Design: ATEX blowers are constructed with non-sparking materials. Critically, all electrical components, including the motor, are housed in robust, flameproof enclosures that contain any potential electrical spark and prevent it from igniting the surrounding atmosphere.

- Guaranteed Oil-Free Operation: Oil mist from a standard blower’s lubrication system can act as a fuel source in an explosion. ATEX-certified blowers for these applications must ensure 100% oil-free air delivery. This is achieved through designs that completely isolate the oil-lubricated gears and bearings from the gas path, eliminating a critical element of the fire triangle.

- Strict Temperature Control: Overheating due to friction or internal compression can create hot surfaces that act as an ignition source. ATEX certification guarantees that the blower’s external and internal surface temperatures will remain safely below the auto-ignition temperature of potential hazardous gases.

- Static Electricity Dissipation: The entire blower package is designed to be properly grounded, preventing the buildup of static electricity a common and often overlooked ignition source.

Why TMVT is Premier Choice for ATEX Roots Blower in Aquaculture

At TMVT, we understand that modern aquaculture demands equipment that delivers both peak productivity and uncompromising safety. Our ATEX-certified roots blowers are engineered from the ground up to meet these dual requirements, making them the ideal solution for today’s advanced fish farms.

- Superior Tri-Lobe Technology: Our 3MTL series blowers feature an advanced three-lobe rotor design. This provides a smoother, less pulsating airflow, which significantly reduces vibration and noise. The benefits are twofold, it creates a less stressful environment for the fish and farm personnel, and the reduced mechanical load extends the life of bearings by up to 20%, ensuring superior reliability.

- Inherently Safe, 100% Oil-Free Design: The safety of your operation and the purity of your water are paramount. The TMVT design features an oil chamber that is physically separated from the main gas chamber, providing an engineered guarantee of 100% oil-free air. This eliminates the risk of oil contamination in your tanks and removes a potential fuel source from the safety equation.

- Robust and Precise Construction: TMVT blowers are built for continuous, heavy-duty operation. We use robust cast iron casings that are stress-relieved after pre-machining to prevent warping and ensure dimensional stability at all operating temperatures. All components are machined to extremely tight tolerances, minimizing friction and maximizing efficiency and service life.

- Certified Safety and Performance: We offer a complete range of blowers that are fully compliant with the ATEX 2014/34/EU directive, providing you with certified and documented explosion-proof protection. Furthermore, every TMVT blower is individually tested at our facility for capacity, power consumption, temperature rise, and vibration levels before shipment, guaranteeing that it will perform to specification from day one.

Conclusion: Integrating Productivity and Peace of Mind

As aquaculture continues to evolve, the line between agriculture and industry blurs. The drive for higher productivity through intensive systems necessitates a more sophisticated approach to operational safety. Choosing an ATEX roots blower for aquaculture is a forward-thinking decision that addresses the real, though often unacknowledged, risks of flammable gas buildup.

By selecting a TMVT aeration blower for your aquaculture operation, you are investing in a solution that is engineered for both maximum productivity and certified safety. Our commitment to quality, precision, and robust design ensures you receive a reliable, efficient, and fundamentally safe machine that provides not only oxygen for your stock, but peace of mind for your entire operation.