Industrial petrochemical plants routinely handle gas streams that are corrosive and potentially explosive, including acidic components and alkaline components . These gases attack ordinary blower material like carbon steel or iron can rust and perforate rapidly in acid or alkaline environments. At the same time many of these gases are flammable. A corrosion-induced leak or mechanical failure in a blower can release toxic, flammable gas into a hazardous Zone, risking ignition and a major incident. Thus, corrosion-resistant, ATEX-certified blower designs are essential in petrochemical service.

- Typical corrosive gases: Petrochemical streams often contain H2S, HCl, SO2, SO3, Cl2, CO2, F2, Nox, NO, NO2, N2O4, COCI2 (Phosgene) being an aggressive species and even ammonia vapours. For example, hydrogen sulphide (from gas wells or sour crude) and chloride-containing gases (from chlorination processes) are common, both can severely corrode metals. The breakdown of acid gases can produce condensate that dramatically accelerates metal attack.

- Effects on blowers: In a Roots blower, corrosion can thin the casing or rotors, leading to leaks or rotor seizure. Build-up of corrosion products on the lobes can imbalance the rotors or reduce volumetric capacity. Any leak into the atmosphere exposes workers to toxic fumes and creates a Zone 1 explosion risk if ignition sources are present.

- Safety hazard: Corrosive gases like H2S are also explosive. For example, waste or flare gases containing acid and hydrocarbon vapours are both toxic and combustible, requiring safe handling by blowers. An ATEX-rated blower must thus not only resist corrosion, but also prevent any ignition. Any flaw due to corrosion could compromise its explosion-proof design.

Engineering Challenges and Corrosion Mitigation

Designing blowers for chemically aggressive atmospheres raises several engineering challenges:

- Material degradation: Standard blower materials can quickly degrade. Acid or alkaline vapours can form rust, pits and cracks on metal surfaces. If moisture is present, corrosion is even faster. Over time this can enlarge clearance gaps or bore holes, increases the amount leakage, puts more load on the gears and bearing which reduces efficiency or causing leaks.

- Sealing and bearings: Corrosive gases can quickly damage standard lip seals or gaskets, leading to leakage and bearing contamination. To prevent this, TMVT uses a multi-layer sealing system:

1) Gas-side mechanical seals or labyrinth seals that resist acid and moisture attack.

2) Isolated oil chambers with splash-lubricated bearings, ensuring that lubricants never come into direct contact with the gas stream.

3) Protective coatings and corrosion-resistant materials on seal housings to extend service life.

4) Optional purge arrangements (using clean, inert gas) in severe service to keep corrosive vapours away from the bearing chamber.

This design not only prevents leakage of corrosive gases but also protects the bearings, ensuring long-term reliability in ATEX Zone 1 environments.

- Temperature and condensation: Some acid gases have high dew points. For example, HCl gas condenses into hydrochloric acid on cooler surfaces. Blowdowns and start-ups must manage temperature to avoid acid condensation inside the blower.

To address these, engineers use a combination of design strategies and materials:

- Corrosion-resistant materials: Key wetted parts (such as rotors, casing, and internal walls) are constructed from or protected with corrosion-resistant alloys and coatings. Depending on the gas composition, TMVT applies solutions such as:

1) 316L Stainless Steel – high resistance to HCl, H₂S, and chloride-rich gases.

2) Nickel Plating – a fine-grained, uniform coating widely used for its superior corrosion resistance.

3) Epoxy and Ceramic Linings – chemical-resistant protective layers applied to internal surfaces to prevent acid or alkali attack.

4) Hard Rubber or Polymer Coatings – effective for certain acidic streams, providing a non-reactive barrier.

By selecting the appropriate combination of alloy and coating, TMVT ensures long-term protection of wetted parts against aggressive petrochemical gases.

- Smooth internal design: TMVT’s tri-lobe rotor design provides a much smoother airflow compared to two-lobe or irregular impellers. This steady flow minimizes sudden pressure fluctuations, which in turn reduces vibration, mechanical stress, and wear on seals. Additionally, the streamlined internal passages and polished surfaces prevent dead zones where corrosive vapours or liquid condensates might accumulate. By avoiding these stagnant pockets, the blower is less prone to localized corrosion, pitting, or build-up of chemical deposits directly extending equipment life and ensuring safer, more reliable operation in corrosive environments.

- Isolation of moving parts: TMVT three-lobe units separate the oil chamber from the gas chamber, so the gas never contacts lubricants. This prevents chemical reaction with oil and ensures no oil forms by-products under acid attack.

- Temperature control: When necessary, blowers can be jacketed or insulated to keep internal metal temperatures above the dew point of acid vapours, avoiding condensation.

Combining these measures means the blower can operate safely in a harsh chemical environment. Proper design reduces corrosion rates, but materials and coatings are the principal line of defence, as discussed next.

Materials and Coatings for Corrosive-Service ATEX Blowers

The choice of construction materials is critical for a Roots blower in corrosive duty. Common approaches include:

- Stainless steel rotors and casings: Stainless alloys are widely used for acid gas service. Stainless resists acids like HCl, H2S and ammonia. For example, 316L SS has molybdenum to resist chloride attack. TMVT can supply blowers with stainless steel internals or even full stainless casings when needed.

- High-alloy steels: In extremely corrosive applications, super-alloys or duplex stainless steels may be used for components. These are more exotic and costlier, but sometimes chosen for the severest acids.

- Ceramic and epoxy linings: Some blowers are lined internally with chemical-resistant coatings. For example, hard rubber, epoxy, or ceramic linings can be applied to the chamber walls and rotors.

- Nickel plating: Electroplating a few microns of nickel on rotors and internals is another technique. Nickel exhibits excellent corrosion resistance. Industry literature notes that nickel has a fine-grain, protective structure and is widely used in electroforming for its corrosion resistance.

- Bronze or aluminium bronze: In some cases, copper alloys are used for parts, since copper resists some acids and does not spark. TMVT’s vacuum pump line offers partial-bronze construction for corrosive services. A similar choice can be made for blower casings or impellers in specialized blowers.

- Coated internals: Apart from full linings, segmented coatings may be applied. For instance, a cast iron housing might be painted with epoxy or ceramic paint. Critical areas receive sprayed or polymer coatings to slow down metal wear.

When selecting materials, TMVT will often ask for the gas composition and specify, for example, a 316L SS rotor set and an epoxy-coated cast housing. The goal is to ensure that every wetted path either is made of a non-corroding alloy or is isolated by a resistant lining.

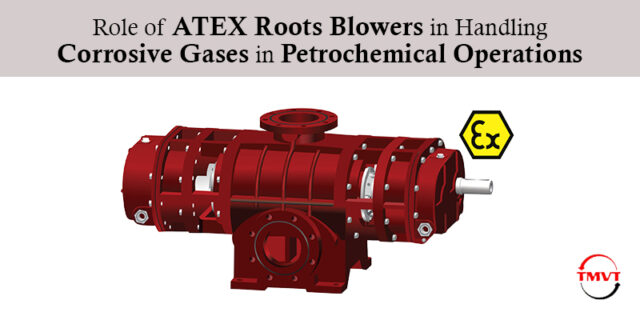

Design Features of TMVT’s Three-Lobe ATEX Roots Blowers

TMVT’s three-lobe Roots blowers incorporate several design features that make them particularly well-suited for corrosive petrochemical service while meeting ATEX safety standards:

- Tri-lobe rotor geometry: The three-lobe design gives a very smooth, almost pulsation-free flow. This steadier flow reduces vibration and mechanical stress. In corrosive gas streams, smoother flow means fewer pressure spikes, which lowers peak stresses on casings and seals. TMVT has measured that three-lobe units have about 20% lower bearing loads and about 5 dB less noise than equivalent two-lobe blowers. Lower vibration also means that seals and linings are less likely to be damaged by oscillation

- Oil-free gas path: All TMVT ATEX blowers, the gas chamber is completely separated from the oil chamber. This ensures 100% oil-free discharge gas. For corrosive gases, its important any lubricant could chemically break down under acid attack, potentially generating carbon residues or seizing up.

- Robust cast construction: TMVT blowers use a heavy-duty cast housing that is stress-relieved during machining. Stress relief prevents distortions at high temperatures or under pressure. The substantial cast body provides a strong barrier; when needed, TMVT can apply protective lining inside the cast cavity.

- Explosion-proof Components: Beyond corrosion resistance, TMVT’s ATEX blowers are engineered with explosion-proof motors, enclosures, and electrical fittings, ensuring no ignition sources in hazardous environments. For sealing, TMVT specifies mechanical seals that meet ATEX compliance requirements either individually certified with an Ex marking or covered under the blower’s overall ATEX declaration. Together, these measures ensure the complete assembly is fully compliant with ATEX Zone 1 safety standards.

- Low heat generation: The tri-lobe profile and precision balancing mean the blower runs cooler and with minimal friction. Lower heat inside the blower means the blowdown stream is less likely to reach temperatures that could ignite or accelerate corrosion.

- Easy maintenance access: TMVT design emphasizes ease of maintenance. A simple, modular construction means blowers can be opened for inspection or relining

- Proven performance: Each TMVT blower is run-tested on a performance bench. This factory testing validates that the machine meets specification before shipping. TMVT’s quality control helps ensure that once installed, the blower will perform as required even under demanding conditions.

In summary, the combination of tri-lobe design and robust ATEX-engineering gives TMVT blowers a reliability edge in handling harmful gases. Features like reduced pulsation and 100% oil-free flow directly support corrosion resistance and safety

Maintenance and Inspection Best Practices

Even the most corrosion-resistant blower requires diligent maintenance in harsh service. Regular inspection and upkeep are vital for long-term reliability:

- Frequent visual checks: Inspect the blower housing and rotors for signs of corrosion, pitting or erosion. Any discoloration, unusual deposits inside the casing can indicate coating breakdown. TMVT blowers often have viewing ports or easy-open covers so an operator can periodically check internal surfaces

- Recoat or replace linings: If internal linings show wear, they should be reapplied. It’s better to patch a tiny breach than wait for a cascade of corrosion behind it. TMVT recommends using the same corrosion-resistant material as originally used to maintain uniform protection.

- Bearing and seal service: Even though bearings are in a sealed oil sump, corrosive gas can sometimes infiltrate small leaks. Use corrosion-inhibiting gear oil, and replace oil filters or breathers if installed.

ATEX Zone Compliance and Corrosion Control

ATEX certification is mandatory for blowers operating in gas hazardous areas (Zones 1 in petrochemical plants). For an ATEX Roots blower, this means:

- No ignition sources: TMVT’s ATEX blowers are designed so that all electrical parts are explosion-proof, and all bearings and gear chambers are fully sealed to prevent sparks. Unlike belt-driven machines which can generate friction, slippage, and static TMVT blowers use a direct drive configuration. This eliminates potential ignition from belts, reduces heat build-up, and ensures safer operation in hazardous petrochemical environments. The overall design also avoids hot surfaces and static accumulation, fully supporting ATEX Zone 1 compliance.

- Preserved enclosure integrity: The blower casing itself serves as a flame barrier. Corrosion can thin or weaken the casing, potentially breaking its ability to contain an ignition. Thus, corrosion control is directly related to explosion protection. A blown seal or perforation due to corrosion could let gas into the motor housing or into open air, creating a dangerous condition.

- Temperature classes: ATEX also sets maximum surface temperatures. Corrosion on hot spots can affect temperature sensors or compensating devices. Maintaining clean, corrosion-free surfaces helps ensure the blower doesn’t inadvertently exceed its temperature rating.

- Zone maintenance: In ATEX Zone 1, equipment is required to be inspected at defined intervals. Part of this is checking that any protective linings or coatings are intact. In practice, a corrosion-resistant blower will more easily remain within compliance over time, because there’s less risk of breach.

In summary, corrosion control and ATEX safety go hand in hand. By using corrosion-resistant materials and coatings, the blower continues to meet ATEX requirements throughout its service life. Conversely, effective corrosion protection reduces unplanned leaks of flammable gas.

Finally, compliance means the blower must have documentation matching its materials and construction. TMVT’s ATEX blowers are supplied with full certification, showing that even with special materials the unit has been tested for Zone 1 use.

Conclusion

Corrosive gas handling is a critical challenge in petrochemical and chemical processing. A standard blower will corrode or fail prematurely when exposed to acid/alkaline vapours By combining advanced materials (316L stainless steel, nickel plating, polymer linings, etc.) with the proven TMVT tri-lobe design, operators get a corrosion-resistant, reliable Roots blower for even the most aggressive gas streams.