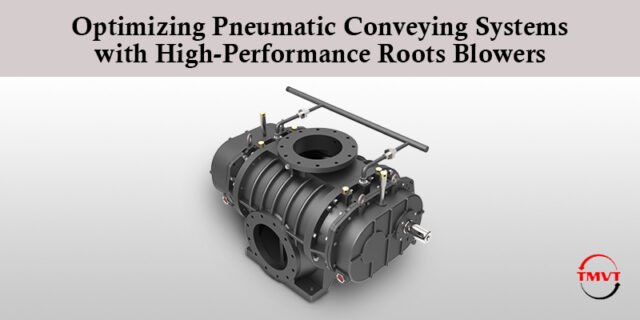

High-performance root blowers are commonly used across pneumatic conveying systems due to some obvious advantages. These include the positive displacement principle, high pressure that enables long-distance conveying, and the straightforward design of blowers.

Some key applications where root blowers are used in pneumatic conveying include dilute phase conveying, dense phase conveying, and vacuum conveying.

However, the industry also uses it to optimize pneumatic conveying machines.

Understanding Pneumatic Conveying Machines

Pneumatic conveying systems are designed to move bulk materials such as granules and powders and dry materials through pipelines by using gas or air. pneumatic conveying machines are used in different industries such as foods processing and pharmaceuticals plastics and chemicals because of their effectiveness and capability to ensure their integrity throughout transport. This process creates an air pressure differential which moves substances from one location in an enclosed pipeline. This creates the environment is clean and free from contamination. Root blowers play an essential part in these systems, providing the airflow required and pressure that allows materials to be conveyed efficiently. They are able to supply a constant uninterrupted, non-pulsation air flow is ideal for heavy and dilute phase conveyance which improves the performance of pneumatic conveying equipment.

Thus, this post particularly focuses on the optimization part, explaining the factors that contribute to it. Here’s more to it.

Maintaining Consistent Airflow and Pressure

Root blowers provide steady and pulsation-free airflow that helps seamlessly move the material through the pipeline. Such consistency reduces the risk of blockages and improves system efficiency, thus optimizing pneumatic conveying performance.

Enhanced Material Handling

Another significant advantage of high-performance root blowers in the context of pneumatic conveying systems is improved material handling.

It enables precision airflow control and pressure that enables root blowers to handle delicate or fragile material without damaging it.

This particularly proves beneficial in industries that deal with critical items like pharmaceuticals and food processing.

Minimized Heat and Noise

High-performance root blowers, particularly those manufactured by responsible manufacturers like TMVT also help reduce heat and noise. These blowers minimize heat generation, and the noise output, helping make the workplace more peaceful and increase the longevity of the blower and associated components.

Energy Efficiency

Lowering energy consumption is one of the most crucial requirements of every modern industrial setup that employs complex machinery and equipment.

Modern root blowers precisely fit this parameter. They are designed to operate with high efficiency helping industries reduce energy consumption while maintaining the necessary airflow and pressure levels.

The long-term dual impact of this attribute is lowered operational costs and adherence to sustainable practices.

Customization and Flexibility

Customization is another crucial element, encouraging industry owners to use root blowers for different pneumatic conveying operations.

Thus, contemporary performant root blowers can be customized to meet the specific requirements of pneumatic conveying systems like variable speed drives (VSDs) to align the airflow, depending on the material load, length of the pipeline, etc.

Durability and Reliability

Pneumatic conveying is a specialized and critical task that demands durable and reliable equipment, of which high-performance root blowers are part.

Manufacturers like TMVT often use robust, premium, and industrial-grade components and sealing technologies that contribute to the blower’s longevity.

It helps make the mechanism more reliable, minimizing potential downtime and enabling seamless operations, while also curtailing maintenance costs significantly.

Compact Design

Space is a major constraint for companies across every industry. Companies look to optimize the available space with smartly sized equipment.

No wonder, there’s a massive demand for compact machinery these days.

High-performance root blowers fulfill this need. They are designed to save space, which is why they are apt for retrofitting into existing systems or companies with limited usable floor space.

Looking to Optimize Your Pneumatic Conveying Machines?

Connect with TMVT for high-performance root blowers to help you achieve the optimization objective!

We are one of the leading manufacturers of performant root blowers that provide three lobe root blowers and twin lobe root blowers to serve the varying and evolving needs of the industrial world.

Our long-running clientele from various industries like pharmaceuticals, food and beverages, chemical processing, cement sector, etc., are a testimony to the success of our offerings and the trust that the industry has in them.

Visit our root blowers page to explore more and click to get a quote.